Electric cars running on salt, but not the table salt you’re thinking of, could soon be possible. The world’s largest manufacturer of EV batteries (CATL) has launched a new sodium-ion battery. This will hopefully replace the lithium-ion battery, solving challenges around current battery construction and recycling processes.

Imagine – your next phone, laptop or electric vehicle (EV) running on a salt battery (or at least sodium rather than lithium)!

What’s the problem with Lithium-ion batteries?

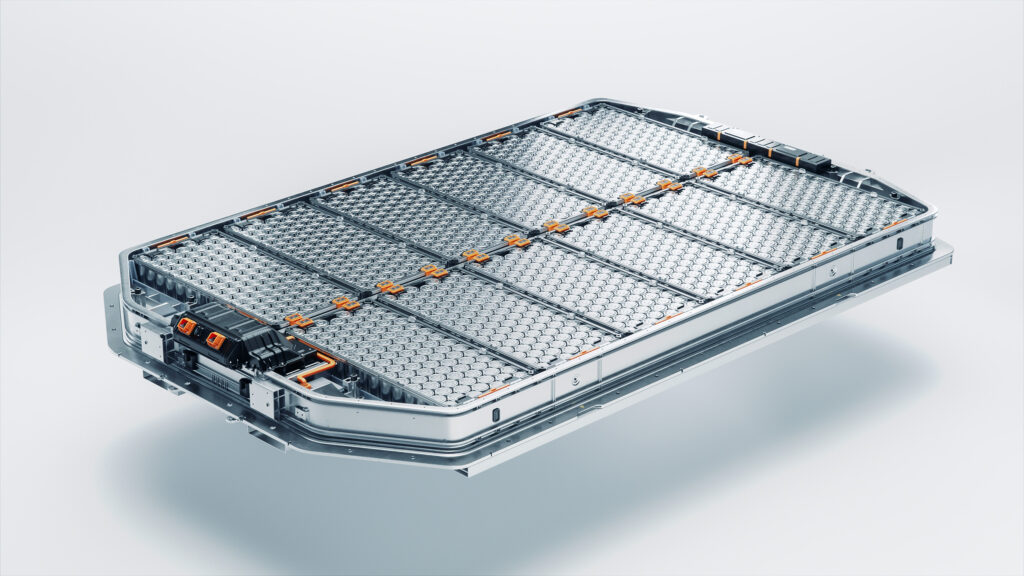

Lithium-ion batteries are in high demand because they’ve become an essential part of the modern world. They revolutionised battery technology in the 1990s, storing more energy for longer and are now responsible for powering several of our modern technologies, including EVs, smartphones and laptops, as well as medical equipment and supercomputers that train Artificial Intelligence (AI).

These batteries are built using reactive elements: lithium, cobalt and nickel, which are challenging to obtain. They easily react with other elements, so they are often mined out of the ground as mineral compounds like lithium chloride. The lithium then needs to be separated from the chlorine before it can be used in a battery, and this is a long process.

Whilst there is the possibility of extracting the elements from the battery after use and recycling it, it currently costs more to recycle a lithium-ion battery than it does to make a new one. Battery parts are constructed using several glues and plastics, making the disassembly process time-consuming, labour-intensive and expensive. One example is the battery of a Nissan Leaf- It can take up to two hours to dismantle, and this is before the recycling process begins.

How are lithium-ion batteries recycled?

At present, all recycling processes involve shredding the batteries down to a powder and either:

- Using high heat to melt the battery and adding a material like flux that reacts with impurities like glues and plastics. This reaction creates a waste product called slag that can easily be removed, leaving a combination of metals (alloy). The alloy can go through further refinement processes until the result is pure lithium. This process, known as Pyrometallurgy, requires large amounts of energy to maintain the high temperature and emits gas pollutants into the atmosphere.

- Dissolving the desired metals into chemical solutions or solvents, leaving impurities like glues to be filtered out. This continues until pure lithium is left. This process, called Hydrometallurgy, presents several potential hazards, including fire and explosion risks.

Even when done properly, these methods produce only a small amount of material that can be reused, resulting in only 5% of Lithium-ion batteries being recycled. This has placed more pressure on finding alternatives to these elements and new ways of assembling batteries that allow easy dismantling.

What innovations are scientists looking at to improve EV battery recycling?

Innovation 1: Battery materials

Scientists and battery manufacturers have developed and launched new sodium-ion batteries, which could reduce lithium demand for EV batteries. Redesigning battery material isn’t new, in the 1990s, the lithium-ion battery replaced lead-acid batteries as Lithium-ion offered higher energy, higher power and better energy storage. The brief for a battery has now changed with sustainability, stability and cost-effectiveness adding to the need for high power and storage.

The world’s largest battery manufacturer (CATL) began production of sodium-ion batteries in 2023, officially launching them in 2025. Since the 2023 declaration, carmakers in China have begun marketing and selling cars using these instead of lithium-ion batteries. But why sodium?

Why sodium salts?

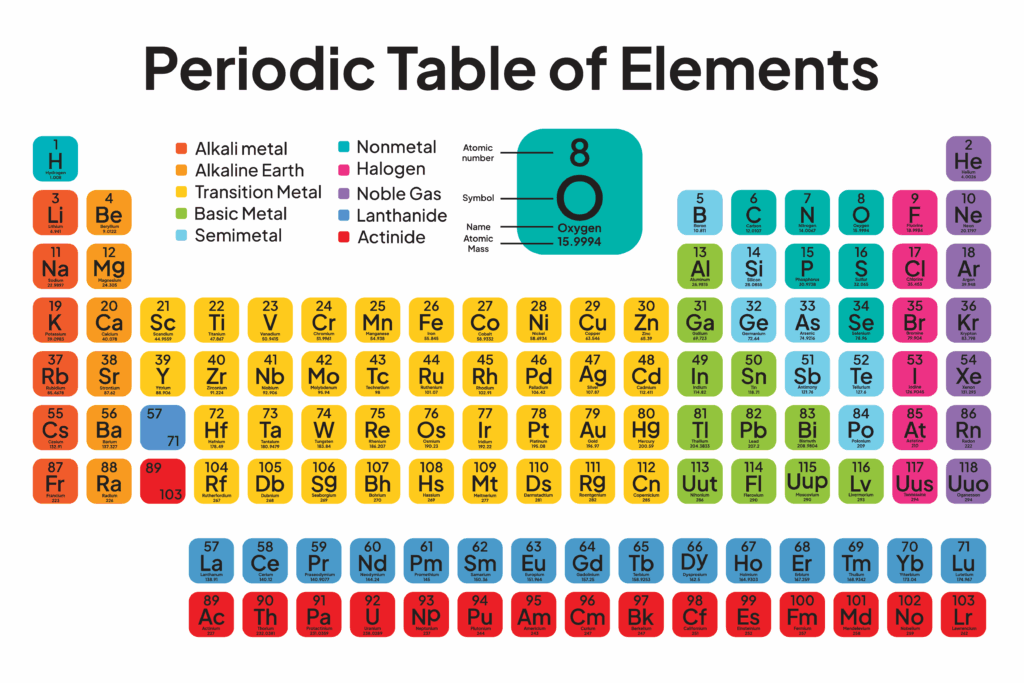

Sodium (chemical symbol: Na) sits just below lithium (Li) in the periodic table of elements, meaning their chemical properties are similar. As a result, scientists can use the same design and manufacturing techniques as lithium-ion batteries, rather than spending time developing lengthy new processes. Sodium is also 1000 times more abundant than lithium. Sodium chloride or salt is an everyday item found in seawater, meaning it’s a much easier resource to collect and use.

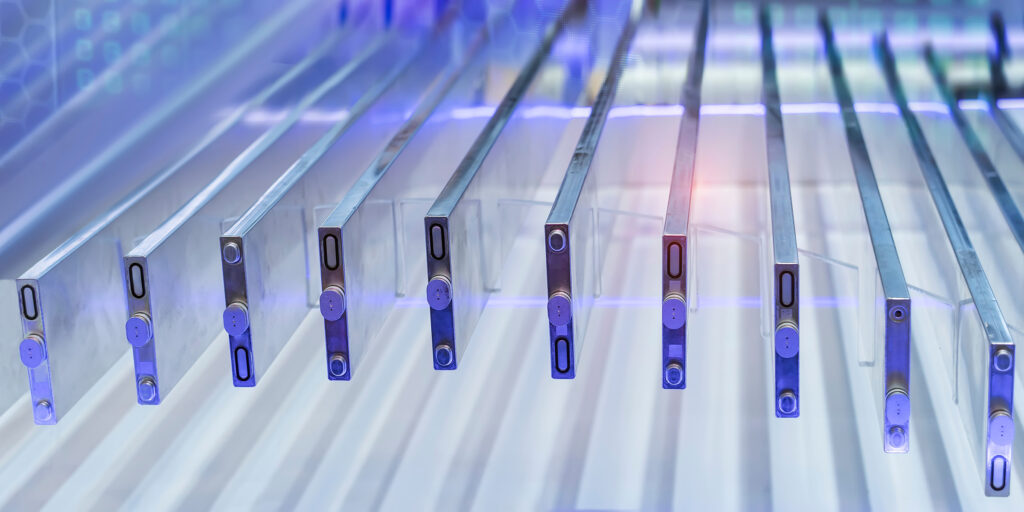

The transition from lithium to sodium batteries for electric vehicles comes with challenges and limitations for manufacturers and scientists. Firstly, sodium ions are larger than lithium ions, so they take up more space. So, fewer sodium ions can fit in the same-sized battery, resulting in a smaller energy capacity. Sodium-ion batteries are yet to last as long as lithium. Current testing suggests that the number of times a sodium battery can be charged and discharged (its lifecycle) is between 300-3000 times, whereas lithium batteries average 3500.

Innovation 2: Battery construction

Scientists and manufacturers are also developing new ways of designing and manufacturing lithium-ion batteries, so they are easier to disassemble and extract metals for recycling.

In 2018, China began to make manufacturers responsible for recycling the batteries powering their EVs. As a result, companies like Auto Co developed a new battery- BYD Blade battery, making the recycling process easier. The Blade battery stores flat battery cells directly inside, and the cells can be easily removed by hand without dealing with wires and glue. China now recycles more lithium-ion batteries than any other country, using the pyrometallurgy and hydrometallurgy methods above.

Whether it is reassessing how a battery is constructed or what materials batteries use, large investments and innovation efforts are being poured into finding safe, sustainable and improved ways of powering the EV market.

One thing is for certain, there will be a significant number of jobs in the design, manufacture and recycling of batteries in the future.

If you would like to explore careers in the energy sector, head to the Energy Careers section of the My Energy Future website.